Difference between Inbound and Outbound Logistics

Logistics play a significant role in the smooth operations of a business. In simple words, logistics can be described as the total of all the activities involved in "getting the right item delivered, at the right time, at the right price, in the right condition to the right customer'.

Role of Inbound and Outbound Logistics in Supply Chain Management:

Logistics is the heart and soul of supply chain management. It helps the corporates manage, coordinate and monitor the resources required to move products in a timely, cost-effective and seamless manner. Reports indicate that in 2019, companies, on average, spent 11% of their revenue on the logistics supply chain. Out of this spending, 72% *s spent on transportation and inventory. A well-organised logistics system can reduce expenses, save time, maximise customer satisfaction and enhance a brand's loyalty.

Types of Logistics:

Depending upon the direction of material flow and the processes involved, there are different types of logistics. Two of the broad types of logistics are Inbound Logistics and Outbound Logistics. The main difference between these two logistics processes is the direction of material flow. While Inbound Logistics brings goods or raw material into the company, Outbound Logistics helps move the finished goods to customers. In simple words, Inbound is all about receiving, while Outbound Logistics is about delivery.

Why Outbound Is So Important in Modern Business

Outbound logistics is vital in modern business because it mainly focuses on the demand side of the supply-demand equation. It directly connects with the customer's ends, including order fulfilment, packing, shipping, and delivery at the customer's doorsteps.

What is Inbound Logistics?

Inbound Logistics refers to the total of all the processes involved in the flow of information, goods and services from suppliers into the production facilities. The various activities include internal operational processes like ordering and procuring raw material, managing vendors, managing inventory, and transporting goods. The inbound process mainly works on the supply part of the products.

Inbound Logistics Activities:

The various activities involved in the Inbound Logistics processes are as follows:

- Sourcing and procurement: Searching the potential suppliers and selecting supplier(s) basis their product quality, product price, credit terms, lead time, vendor reliability and other such factors.

- Ordering/purchasing: Placing the order as per the requirement and noting it. It is essential to take a tracking system in place. While placing the order, it is crucial to mention the date, location and other packing instructions.

- Receiving: Once the goods arrive at a warehouse, the warehouse in charge receives the goods. The in-charge needs to verify that the products are as per the delivery challan in number and specifications.

- Put-away: Once this check is done, the products are logged in and stowed at the proper location. Most good logistics companies like Varuna Group use the inventory tracking system to help track when and how much inventory has arrived at the warehouse.

- Storing and warehousing: Inside the warehouse, the materials are stored in such a manner that they can be moved for the manufacturing process without any delay in locating or moving them. This requires placing the products at their designated places. Modern logistics companies like Varuna Group use bots and automation tools to make this process easy, quick and error-free.

- Inventory management: Carrying a huge inventory only does not involve costs. There are some costs involved in carrying the inventory. These costs are called Inventory Carrying Costs. To keep these costs in check, it is crucial to follow the inventory management guidelines and principles to maintain a regular and cost-effective flow of raw materials into manufacturing.

- Reverse logistics: Off late, this has become an important aspect of Inbound Logistics. It gets initiated when a customer wants to return or exchange a product. It involves picking the original goods from the customer, bringing them to the warehouse, and re-stocking it in the inventory. Customer-focused companies like Varuna Group offer a customer helpline to support customers in case of any doubt or query.

Challenges of Inbound Logistics:

Like everything, inbound logistics has a few challenges

- High transportation cost

- Miscommunication with the supplier, manufacturer and operational team

- Lack of appropriate information regarding the shipments

- Fluctuation in supply and demand

- Increased risk of the return process

How to Optimise Your Inbound Logistics:

For organisations looking to make their logistics cost-effective, it is critical that they make their operations fast, cost-efficient and more agile. This involves examining each activity critically in an unbiased manner and working towards suggestions to improve.

Given below are some tips to optimise the Inbound Logistics Process:

- Building strong relationships with suppliers: This can help you get reliable service with better credit terms, reduced lead time, cost savings and a sense of security during market fluctuations.

- Developing and Implementing Vendor Inbound Compliance Standards (VICS): Asking your suppliers to sign the VICS can help you optimise the process. It rewards positive behaviour and includes penalties for breaking the guidelines. This forces the vendors to take your business and supplies seriously.

- Using Transportation Management System (TMS) for dynamic freight charges: TMS helps companies get access to changing rates offered by different carriers. These rates are often dynamic and subject to various market conditions. This helps companies get the best possible rates and keep their costs in check.

- Consolidating small inbound deliveries: Getting a less-than-truckload (LTL) shipment is inefficient and results in unnecessary expenses in transporting and unloading the goods. Hence, the companies should try to consolidate smaller shipments into one big shipment.

- Using of Warehouse Management System (WMS): WMS optimises the entire warehouse operations by streamlining each activity like receiving, put-away, inventory management, picking, among others.

What is Outbound Logistics?

The term Outbound Logistics refers to the total of all the processes involved in the flow of information, finished product or service from production facilities to the next link in the supply chain. The various activities include packaging, warehousing, and transporting to the customer location. Outbound logistics refers to the demand side of the supply-demand equation.

Outbound Logistics Activities:

- Warehouse and Storage Management: Outbound Logistics plays a significant role in keeping the product supply secure in the right conditions with a certain quantity on hand to meet the customers' demand. They deal with the outgoing finished ordered product.

- Order Processing: When an order is received, details are fed into WMS. This order gets into the queue and gets processed as per its turn.

- Product Picking and Packing: The products are picked from their location in the warehouse, and necessary entry is made in the system to update the inventory. Then, the product is packed as per the packing instructions mentioned in the order sheet.

- Shipping out packed goods: Once the goods are packed, they are labelled and sorted as per delivery location and mode of transportation.

- Delivery: The carrier picks up the goods and delivers them to the customers. To ensure the success of the entire logistics process, the right product must get delivered to the right customer safely and on time.

- Last-mile Delivery: The last mile is the most costly and inefficient part of the delivery. This deals with the home grocery delivery from a local store and package delivery by a common carrier. Before the last mile, shippers can handle many orders simultaneously in the same way (for example, they can load dozens of orders going to the same city in one truck). But in the last mile, each delivery requires individual handling because it goes to a single address.

Challenges of outbound Logistics:

Some significant challenges of outbound logistics services are:

- Monitoring and synchronising various processes

- Delay at pickup and delivery

- sharing real-time data of the product with the customers for tracking and tracing

- Maintaining sufficient inventory to fulfill the demand for products

- Vehicles breakdown and unavailability of drivers

- Last moment changes in the route

How to optimise your outbound Logistics:

To optimise outbound logistics, we need to make better use of technology for updating delivery networks & planning proper routes.

Given below are some tips to optimise the Outbound Logistics Process:

- Reducing turnaround time: Time is as important as money in logistics services. Hence, it is critical to plan the logistics in such a way that there is no unproductive time. When delivering the goods, you need to know whether or not your customer will use a lumping service so that you can account for these extra costs. The main idea is to reduce the TAT, let the drivers rest and start quickly.

- Adapt to current inventory strategies: Rapid replenishment techniques like JIT help companies manage their inventory cost and space better. But, in such cases, the orders are generally small. So, the company loses on the benefits of full-truck-load (FTL). The company has to account for more frequent LTL orders.

- Build and improve partner relationships: It always pays to have deeper relationships with your partners, including freight service providers. Having established the relationships, the customers may offer valuable market information that may help you fine-tune your production, order fulfillment and shipping. Working closely with a few freight carriers can give you better control over price and service level agreements.

- Use smart route planning: Using automation in route planning helps companies decide the best route for shipping. This can reduce the time for delivery and waiting and reduce fuel expenses. All this work together to enhance customer satisfaction.

- Consider 3PL as an option: For most companies, the cost and complexities of outbound logistics can be quite a challenge. It makes huge business sense for such companies to outsource their logistics service to a 3PL service provider. Reputed logistics companies like Varuna Group bring expertise, knowledge and specialisation to make your process seamless and cost-efficient.

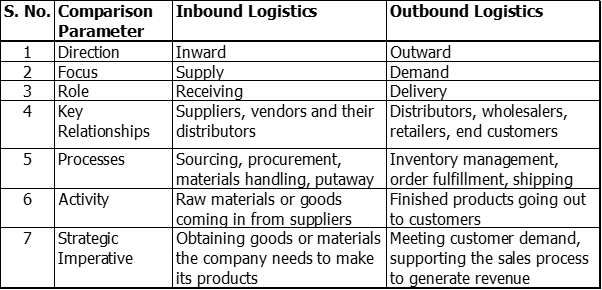

Critical Differences between Inbound and Outbound Logistic

Contact us today for detailed insights on how Varuna Group can support your business.

FAQs:

Inbound logistics refers to the internal operational process of sourcing raw materials and managing the entire flow of the production process to complete the order.

Outbound Logistics refers to the various processes that involve storing and moving goods to the customer or end-user. The various steps included in outbound logistics are - order fulfilment, packing, shipping, delivery and customer service related to delivery.

Both types of logistics work as pillars of the company's supply chain. To ensure businesses are working with the best suppliers, we need a sound inbound logistics system. To keep customers happy and buying, more effective outbound logistics are required.

Every process, including transport, storage and material or goods coming into the business, is counted under inbound logistics. Outbound logistics refers to the going out of products from the business. In simple words, all activities related to product entering the company is Inbound Logistics and activities related to product moving out of the

company is Outbound Logistics.

*Source: https://www.netsuite.com/portal/resource/articles/inventory-management/inbound-outbound-logistics.shtml